Product Search

Catalog

We provide full product details and specifications in catalog format for your convenience.

AUTOMATION

MACHINE TOOLS

CNC machine tools are used to perform precise cutting, drilling, and milling operations on metal and other materials

SEMICONDUCTOR

High-precision wafer and chip manufacturing

AUTOMOTIVE

Automotive assembly production/

Automotive aftermarket

AIR BRAKE SYSTEM

Air Brake System

HARDWARE

DIY materials, construction, and furniture industries

CONSTRUCTION

Air hoses enhance workflow efficiency on construction sites

FOOD

For conveying food-grade liquids - water, cola, beer

HYDRAULIC

Use fluid pressure to transmit force and control industrial machinery

IRRIGATION

Applied in agricultural irrigation, fertigation, and drainage systems

SOLUTION

ABOUT US

MANUFACTURER

Precision-made. Consistently reliable.

SERVICE

Product consulting. Fast support. Tailored solution.

LOGISTICS

Flexible shipping. Global reach.

QUALITY

High-standard testing. Quality assured.

R&D

Ongoing innovation. Reliable solutions.

SHPI Project Experience - Why Stable Taiwan Manufacturing Matters in Today’s Supply Chain

Strengthening Supply Chain Resilience with Proven Taiwan Excellence

Built for Long-term Reliability, Not Just Short-term Gain

In an era of global supply chain restructuring, industrial leaders increasingly prioritize stability,

consistent quality, and enduring partnerships. SHPI, a premier Taiwanese manufacturer with over 40 years

of expertise, specializes in pneumatic tubing, reinforced hoses, and specialized accessories. We empower

B2B clients to establish stable, compliant, and scalable supply systems.

As the new trade landscape evolves, SHPI’s Made in Taiwan (MIT) foundation offers mature manufacturing

capabilities to support your long-term procurement and risk management strategies.

Cross-Industry Fluid Power Expertise

SHPI is more than a manufacturer; we are your technical partner in Fluid Power applications, backed by

extensive experience in diverse industrial sectors.

Semiconductor & Electronics: Providing high-purity, chemical-resistant PA12 (Nylon 12) and PE (Polyethylene) tubing designed for

rigorous chemical handling and precision manufacturing environments.

Automation & Industrial Manufacturing: For high-speed robotics and automated systems, we offer fatigue-resistant PU (Polyurethane) tubing

tailored to specific conditions:

PU-Ester: High mechanical strength and superior oil resistance.

PU-Ether: Excellent hydrolysis resistance, ideal for high-humidity or wash-down environments.

Automotive Repair & Construction: Proven performance in high-abrasion environments with our Reinforced PU Air Hoses, Cold-Resistant

Hybrid Hoses, and industrial accessories.

Commercial Vehicles & Transportation: For safety-critical truck and trailer systems, SHPI provides D.O.T. compliant straight and coiled air

brake hoses, along with dedicated D.O.T. fittings to meet strict regulatory standards.

Why Partner with SHPI?

B2B procurement is about balancing quality, cost, and risk. SHPI delivers value through:

Stable MIT Production: A reliable manufacturing ecosystem based in Taiwan.

Quality Consistency: Performance that rivals leading European and Japanese suppliers.

Flexible Manufacturing: Agile support for OEM and project-based requirements.

Compliance Support: Comprehensive technical documentation and industrial regulatory alignment.

We don't chase short-term market fluctuations. Instead, we focus on sustainable manufacturing partnerships

that safeguard your production lines and mitigate supply chain risks.

Your Long-term Manufacturing Partner

Whether upgrading an automated system or managing a large-scale transportation project, the SHPI team

provides immediate technical support and reliable mass-production execution.

When stability matters more than short-term pricing, SHPI delivers the manufacturing value to help your

business go further.

CONTACT SHPI NOW >

→ Further Reading | PU Tube FAQ — 15 Common Technical Questions by Automation Engineers

→ Further Reading | How to Prevent Production Line Downtime | SHPI Pneumatic Tubing & Fittings Guide

.shpi-article {

font-family: Arial, sans-serif;

font-size: 14px;

font-weight: 400;

color: #222;

line-height: 1.75;

max-width: 980px;

margin: 0 auto;

}

.shpi-article h1,

.shpi-article h2,

.shpi-article h3 {

font-family: Arial, sans-serif;

color: #111;

line-height: 1.3;

margin: 0;

}

.shpi-article h1 {

font-size: 24px;

font-weight: 700;

margin: 0 0 14px 0;

}

.shpi-article h2 {

font-size: 20px;

font-weight: 700;

margin: 18px 0 10px 0;

}

.shpi-article h3 {

font-size: 18px;

font-weight: 700;

margin: 16px 0 8px 0;

}

.shpi-article p {

margin: 8px 0 12px 0;

}

.shpi-article ul {

margin: 8px 0 12px 20px;

padding: 0;

}

.shpi-article li {

margin: 6px 0;

}

.shpi-article .divider {

border: 0;

border-top: 1px solid #ddd;

margin: 18px 0;

}

.shpi-article .tagline {

font-family: "Times New Roman", Times, serif;

font-size: 16px;

font-weight: 700;

font-style: italic;

margin: 6px 0 14px 0;

color: #111;

}

Read More

【Notice】2026 New Year’s Day Holiday

In observance of New Year's Day (Republic of China Constitution Day), SHPI's operating schedule is arranged as follows:

December 31, 2025 (Wed.): Annual inventory check

(Shipment and shipment-related operations will be suspended)

January 1, 2026 (Thu.): National holiday

If you have any questions, please leave us a message via “Contact SHPI NOW” below.

Thank you for your understanding and cooperation.

We wish you a happy and prosperous New Year.

CONTACT SHPI NOW >

Read More

PU Tube FAQ — 15 Common Technical Questions by Automation Engineers

Q1. What are the two PU materials? How do Ester and Ether differ?

Technical Summary

Ester-based and Ether-based PU differ primarily in moisture-related behavior and typical operating environments.

Engineering Rationale

Ester-based PU is commonly used in dry pneumatic systems and is often evaluated where abrasion, friction, or lubricated air (oil mist) is present.

Ether-based PU has low moisture absorption and strong hydrolysis resistance, and is typically evaluated where humidity, condensation, wet compressed air,

or outdoor exposure may affect long-term material behavior.

Typical Selection Considerations

Humidity / wet compressed air / outdoor exposure → Ether-based PU

Dry environments with oil mist (lubricated air) → Ester-based PU

Q2. Do PU tubes absorb moisture? Will it shorten service life?

Technical Summary

Moisture response differs by PU type: Ester-based PU is more sensitive to long-term moisture exposure, while Ether-based PU typically shows minimal moisture absorption.

Engineering Rationale

Prolonged moisture exposure can trigger hydrolysis in Ester-based PU over time, which may gradually change flexibility and mechanical strength.

Ether-based PU resists water absorption and tends to maintain more stable long-term material behavior in humid or wet-air conditions.

Typical Selection Considerations

Controlled dry compressed air → commonly evaluated Ester-based PU

Humid environments / wet compressed air / condensation risk → typically evaluated Ether-based PU

Q3. Can PU tubes burst because of moisture in pneumatic air?

Technical Summary

Moisture alone typically does not cause sudden failure; risk is more often associated with long-term material degradation combined with pressure or mechanical stress.

Engineering Rationale

The primary moisture-related concern is long-term hydrolysis in Ester-based PU. If mechanical strength is reduced over time, pressure spikes, vibration,

or fitting pull-out may increase the likelihood of rupture depending on installation quality and system duty cycle.

Typical Selection Considerations

Humid conditions / wet compressed air → typically evaluate Ether-based PU.

For additional isolation and maintenance convenience, consider shut-off fittings where appropriate for the system design.

Q4. What is the typical service life of PU tubing?

Technical Summary

Service life is application-dependent and is strongly influenced by operating environment and duty cycle.

Engineering Rationale

Humidity, UV exposure, temperature, and cycling stress all influence long-term aging behavior.

Ether-based PU is typically evaluated where moisture stability is a dominant factor;

Ester-based PU is commonly used in dry conditions where routing includes movement, friction, or oil mist exposure.

Typical Selection Considerations

Plan periodic inspection based on duty cycle. Typical aging indicators include whitening, haze, hardening, cracking, or permanent deformation.

Q5. How do PU, Nylon 6 (PA6) and Nylon 12 (PA12) compare?

Technical Summary

PU is commonly selected for routing flexibility; PA6 is commonly used for fixed routing in dry environments;

PA12 is typically evaluated where higher pressure capability and moisture stability are required.

Engineering Rationale

Each material addresses a different tubing role in pneumatic systems (dynamic routing vs. fixed routing, pressure requirements, and moisture response).

Always confirm ratings against the specific OD/ID and operating temperature.

Full comparison:

Property

PU

PA6

PA12

Flexibility

⭐⭐⭐⭐⭐

⭐

⭐⭐

Pressure Rating

⭐⭐⭐

⭐⭐⭐⭐

⭐⭐⭐⭐⭐

Temperature Resistance

~65°C

~80°C

~93°C

Moisture Absorption

Ester: High

Ether: Low

High

Low

Bend Radius

Smallest

Largest

Medium

Typical Applications

Automation, dynamic motion

Dry, fixed lines

Main air lines / high pressure

Cost Level

Medium

Medium

Medium-High

Typical Selection Considerations

Tight bending / dynamic routing → PU

Fixed routing → PA6

Higher pressure / main lines → PA12

Q6. Can PU be used in food-processing equipment?

Technical Summary

Food-contact applications require certified food-grade materials; Ether-based PU is commonly evaluated where moisture stability is also required.

Engineering Rationale

Moisture stability can be relevant in washdown or humid environments, but food-contact use depends on meeting the required food-contact compliance and certification

for the target market and process.

Typical Selection Considerations

Confirm the required food-contact compliance, then request food-grade Ether-based PU if moisture stability is a key operating factor.

Q7. Can PU tubes transport liquids?

Technical Summary

Ester-based PU is typically evaluated for air service; Ether-based PU is commonly evaluated for water service. Chemical media requires chemical compatibility verification.

Engineering Rationale

Ester-based PU may hydrolyze in water over time. Ether-based PU is more stable in water, but chemical compatibility varies widely by chemical type,

concentration, temperature, and exposure duration.

Typical Selection Considerations

Water → typically evaluate Ether-based PU

Oils / chemicals → request SHPI chemical compatibility verification

Q8. Which PU type is better for oil-mist environments?

Technical Summary

Ester-based PU is commonly selected for lubricated air or oil-mist environments.

Engineering Rationale

Ester-based PU is typically evaluated for oil-mist exposure where swelling or mechanical property changes must be managed. Ether-based PU is primarily evaluated

for moisture-driven stability.

Typical Selection Considerations

Oil-mist / lubricated air → Ester-based PU

Q9. How is working pressure determined for PU tubes?

Technical Summary

PU tubing pressure ratings are defined by tube size, wall thickness, hardness, and temperature; published working pressure should be applied with appropriate derating.

Engineering Rationale

Working pressure is affected by wall thickness, hardness, OD/ID, and operating temperature. Higher temperature generally reduces pressure capability.

Example:

Specification

W.P.

B.P.

US805025M (8 × 5 mm, PU Ester)

15 bar

45 bar

Typical Selection Considerations

Follow SHPI W.P. ratings and apply temperature derating where applicable.

Q10. Does tube hardness affect performance?

Technical Summary

Tube hardness affects stiffness, routing behavior, and pressure capability; selection should match the installation role and bending requirements.

Engineering Rationale

Higher hardness generally increases stiffness and pressure capability but reduces flexibility.

Lower hardness improves routing and bending behavior but can reduce pressure capability depending on tube geometry and temperature.

Typical Selection Considerations

• High-pressure fixed lines → commonly evaluate higher hardness

• Tight bends / movement → commonly evaluate lower hardness

SHPI PU tubes are engineered with a balanced hardness window commonly used for automation and pneumatic tools. This balance supports:

Good abrasion resistance

Ease of routing and installation

Stable pressure performance

Elastic recovery with low permanent deformation

Q11. Can PU tubes be used outdoors?

Technical Summary

Ether-based PU is commonly evaluated for outdoor use where humidity and moisture exposure are key operating factors.

Engineering Rationale

Outdoor conditions can include humidity, condensation, temperature cycling, and UV exposure.

Ether-based PU typically maintains more stable behavior under moisture exposure. UV performance depends on formulation and color selection.

Typical Selection Considerations

Outdoor with humidity exposure → typically evaluate Ether-based PU (darker colors are commonly used for additional UV screening depending on formulation)

Q12. Will PU tubes deform when over-bent?

Technical Summary

Yes — bending below the minimum bend radius can cause deformation and increased flow restriction.

Engineering Rationale

Over-bending can flatten the tube, increase pressure loss, and introduce stress concentration.

Typical indicators include whitening, haze, or cracking initiation depending on duty cycle and environment.

Typical Selection Considerations

Follow SHPI bend-radius guidance and avoid routing that forces the tube below its minimum bend radius during operation.

Q13. What fittings are compatible with PU tubes?

Technical Summary

PU tubes are widely compatible with standard pneumatic fittings; fit and retention depend on OD tolerance, cut quality, and correct insertion depth.

Engineering Rationale

PU elasticity supports sealing and retention in push-in fittings, valves, and shut-off fittings, provided that tube OD tolerance and installation practice are controlled.

Typical Selection Considerations

For consistent installation feel → SHPI one-touch fittings

Q14. When should PU tubes be replaced?

Technical Summary

Replacement timing is typically based on observed aging indicators and the system’s risk level rather than a fixed calendar interval.

Engineering Rationale

Whitening, cracks, hardening, haze, or deformation can indicate loss of mechanical integrity and increased failure risk, especially under pressure cycling or vibration.

Typical Selection Considerations

Replace when aging indicators appear. Use batch tracking and maintenance records where controlled replacement practice is required.

Q15. How do I choose between Ester and Ether if I am unsure?

Technical Summary

Selection is typically driven by the dominant operating factor: moisture exposure versus oil-mist/abrasion exposure.

Engineering Rationale

Ether-based PU is typically evaluated for humidity, condensation, or wet compressed air where hydrolysis risk must be managed.

Ester-based PU is commonly used in dry pneumatic systems, and is often evaluated where abrasion and lubricated air (oil mist) are present.

Typical Selection Considerations

Humidity / wet compressed air → Ether-based PU

Wear / oil mist exposure → Ester-based PU

Share operating conditions (humidity, pressure, temperature, bending profile, and media exposure) with SHPI for a selection check.

Read More

Behind a Concert Stage: How Pneumatic Systems, PU Tubing, Nylon 12 & Quick Fittings Make It Work

“Let's go to a concert!”

In

recent years, concerts have practically become a national pastime. From

dramatic lighting, moving stage platforms, to the emotional energy of a

stadium-wide singalong—concerts create moments we fully immerse in.

But—have you ever wondered…

When you finally walk into the venue with excitement, have you ever thought:

How is a concert stage built?

How do indoor and outdoor

stages differ?

What system ensures every

movement is precise, safe, and flawless?

A concert stage is essentially a temporary industrial automation system

From setup → rehearsal → the live show, pneumatic systems play an irreplaceable role throughout the entire process.

Every phase of a concert—from building the stage to the final performance—requires different pneumatic equipment.

For outdoor stages that must be constructed from scratch, the pneumatic system takes on completely different tasks at each stage.

1. Stage

Setup: Pneumatic Tools Do the Heavy Lifting

During

truss assembly, LED wall installation, and frame construction, crews rely heavily on pneumatic impact

wrenches, cutters, and nailers.

They need hoses that are:

Resistant to foot traffic and dragging

Hard to rupture

Stable in airflow and volume

Commonly Used Hose Assemblies:

✅ Reinforced PU Air Hose Assemblies

✅ Hybrid PVC Air Hose Assemblies

2. Rehearsal & Adjustment: Platforms, Lifts and Mechanisms Move Into Action

Lifts, trapdoors, rotating stages, and moving platforms all rely on pneumatic cylinders and valves.

Tubing requirements include:

Pressure resistance and dimensional stability

Flexibility for repeated movement

High sealing performance and quick installation

Tubing / Fitting

Key Characteristics

Nylon 12 Tubing (PA12 Tubing)

High pressure stability, minimal deformation

Polyurethane Tubing Ester

Flexible, oil/abrasion resistant

Polyurethane Tubing Ether

Hydrolysis-resistant, suitable for moisture

One Touch Fittings (Push-in Fittings)

Excellent sealing, quick and tool-free installation

Speed Controllers

Controls cylinder motion speed

Check Valves

Prevents backflow, adds safety

At this stage, the durability of the tubing and the sealing performance of the fittings directly determine the safety of the stage mechanisms.

3. Live Performance: 80%

of Stage Effects Are Pneumatically Driven

Rising, dropping, firing, pushing, inflating — Most of these effects rely on pneumatic power.

So what types of tubing and fittings are typically used to support these stage effects?

Stage Effect

Pneumatic Requirement

Common Tubing

CO₂ Jet

Low-temperature flexibility

Reinforced PU Air Hose

Confetti Shooters

Medium–low pressure, fast response

PU Tubing Ester

One Touch Fittings

Air Ram Launcher

High-pressure impact

R7 / R8 Hydraulic Hose

Inflatables

Continuous airflow

PU Tubing Ester

Nylon 12 Tubing

One Touch Fittings

Speed Controller

Check Valve

Stage Lifts

Stable control

Using the appropriate tubing for each section, such as:

R7 / R8 Hydraulic Hose

Reinforced PU Air Hose

Nylon 12 Tubing

Why Pneumatics Instead of Pure Electric Systems?

The reasons are simple:

Faster response for instant effects

Safer failure mode than electrical systems

Fast setup/teardown for touring productions

Next time—when you're scrolling your phone before the show starts, take a second and imagine how many systems are moving beneath the stage.

You'll realize that every lift, burst, push, and inflation is powered by a precise and reliable pneumatic system.

If you're planning or upgrading your pneumatic setup and need guidance on tubing or fittings, SHPI is here to help.

For 40 years, we' ve focused on reliable tubing and fittings—supporting stable and safe pneumatic systems worldwide.

Contact SHPI — The Tubing & Hose Expert.

CONTACT SHPI NOW >

/* 全域字型與內文大小 */

.article-container {

font-family: Arial, sans-serif;

font-size: 14px;

color: #222;

line-height: 1.6;

}

.article-container h1,

.article-container h2,

.article-container h3 {

font-family: Arial, sans-serif;

margin: 16px 0 8px;

}

.article-container h1 {

font-size: 24px;

font-weight: bold;

}

.article-container h2 {

font-size: 20px;

font-weight: bold;

}

.article-container h3 {

font-size: 18px;

font-weight: bold;

}

.article-container p,

.article-container li {

font-size: 14px;

}

.article-container ul {

padding-left: 20px;

margin: 8px 0 16px;

}

.article-container hr {

margin: 24px 0;

border: none;

border-top: 1px solid #ddd;

}

/* The Tubing & Hose Expert 特殊字型設定 */

.brand-tag {

font-family: "Times New Roman", serif;

font-size: 16px;

font-weight: bold;

font-style: italic;

}

/* 表格區塊樣式(米色調) */

.spec-block {

display: flex;

justify-content: center;

padding: 24px 0;

background: #F7F3EB;

margin: 16px 0;

}

.spec-card {

max-width: 900px;

width: 100%;

background: #ffffff;

border-radius: 14px;

padding: 24px 20px;

box-shadow: 0 6px 18px rgba(0, 0, 0, 0.08);

border: 1px solid #e5e5e5;

}

.spec-title {

font-size: 18px;

margin: 0 0 6px;

}

.spec-subtitle {

margin: 0 0 16px;

color: #666;

}

.spec-table-wrap {

overflow-x: auto;

}

.spec-table {

width: 100%;

border-collapse: collapse;

}

.spec-table th {

background: #E3DCCC;

padding: 10px 12px;

text-align: left;

border-bottom: 2px solid #D0C7B8;

font-weight: bold;

color: #333;

white-space: nowrap;

font-size: 14px;

}

.spec-table td {

padding: 10px 12px;

border-bottom: 1px solid #e2e2e2;

color: #444;

vertical-align: top;

font-size: 14px;

}

.spec-table tbody tr:nth-child(even) {

background: #FAF7F2;

}

.spec-table tbody tr:hover {

background: #EFE8DD;

transition: 0.2s;

}

.item-name {

font-weight: bold;

color: #222;

}

@media (max-width: 640px) {

.spec-card {

padding: 18px 14px;

}

.spec-table th,

.spec-table td {

padding: 8px 10px;

}

}

Read More

From Farm to Table: The Role of Air Tubing in Modern Poultry Processing Lines

Behind Every Roasted Chicken: The Invisible Contribution of Food-Grade Pneumatic Tubing

Every year on the fourth Thursday of November, ovens across North America roast a golden turkey—an unmistakable symbol of gratitude and togetherness. But behind that holiday centerpiece is another, unseen “line of operation”: a system built on pneumatics, technology, and hygienic automation that helps each turkey move safely and precisely from farm to table.

You may not realize it, but the United States is one of the world's largest turkey producers. More than 200 million turkeys are processed and packaged each year on tightly controlled, automated production lines. In these environments, tasks such as conveying, positioning, portioning, sealing, labeling, and weighing rely heavily on pneumatic systems. Cylinders, solenoid valves, and sensors work in coordination—and the critical pathway that connects components and delivers the air supply is the air tubing.

Using a turkey processing line as an example, this article explains typical configurations for food-grade air tubing under different operating conditions, along with the practical material-selection logic used in real-world applications.

Typical Configuration Requirements and Pressure Conditions in Food Processing Lines

In food processing facilities, the primary function of pneumatic tubing is to deliver compressed air steadily and consistently to various pneumatic components. In addition to pressure resistance, tubing materials must also withstand exposure to moisture, oil mist, and frequent cleaning procedures, while maintaining stable performance during long-term operation.

Common Tubing Sizes

Across different processing areas and equipment types, commonly used tubing sizes in food processing lines include 1/4", 5/16", and 3/8" (approximately 6.4–9.5 mm).

Typical Operating Pressure Range

Operating pressure is typically within the range of 100–150 psi (approximately 7–10 bar).

Within this range, tubing selection still requires consideration of the actual operating environment and motion characteristics of the system.

Food-Grade Tubing Selection Based on Operating Environment

In food processing lines, operating conditions such as temperature, humidity, cleaning frequency, and motion behavior vary by area. As a result, tubing selection is commonly differentiated based on actual operating environments rather than treated as a single material standard.

Continuous Operation at Ambient Temperature

In packaging, labeling, and conveying sections operating under ambient conditions, PU Ether (hydrolysis-resistant polyurethane) tubing is commonly used. It provides good flexibility and maintains stable material behavior in humid operating conditions, making it suitable for high-cycle continuous operation.

High-Pressure Lines and Pneumatic Actuation Zones

In areas involving high-pressure main lines, pneumatic cylinders, or driven mechanical assemblies, PA12 (Nylon 12) tubing is commonly selected to meet stability requirements under long-term load conditions.

Cleaning or Low-Temperature Static Areas

In CIP cleaning systems or low-temperature operating areas, where humidity is high and temperature variation is present, LDPE (Low-Density Polyethylene) tubing is commonly used as a pneumatic tubing option in practical applications.

Typical Tubing Configurations in Turkey Processing Lines

PU Ether Tubing: Packaging, Sealing, and Labeling Equipment

PU Ether tubing is commonly used in packaging sealing machines and labeling equipment, where it maintains stable air pressure under frequent on–off actuation.

PA12 Tubing: Pneumatic Push Mechanisms, Cutting Modules, and Reject Units

PA12 tubing is widely applied in pneumatic push mechanisms, cutting modules, and reject units, maintaining stable pressure and motion accuracy under long-term load conditions.

LDPE Tubing: CIP Cleaning Systems and Low-Temperature Zones

LDPE tubing is commonly configured in CIP cleaning systems and low-temperature operating areas, serving as a pneumatic tubing option corresponding to these operating conditions.

Planning Food-Grade Pneumatic Tubing Solutions

Further Reading: Selection Considerations for Pneumatic Tubing in Food Automation Lines

When planning food processing lines, the selection of pneumatic tubing typically requires integrated consideration of material behavior, operating environment, and cleaning conditions, based on the actual requirements of the production line.

→ Further Reading | PU Tubing Material Structure and Engineering Selection

→ Further Reading | Nylon Tubing (PA Tubing / Nylon Tubing) Material Behavior Differences and Engineering Selection

→ Further Reading | PE Tubing (LDPE) Applications in Humid and Low-Temperature Environments

Read More

Pink Coiled PU Air Hose

Product

Highlights

SHPI's Pink PU Coiled Air Hose blends style with professional quality.

It's made for air tools, automotive workshops, and machine tool maintenance, keeping your workspace cleaner and your workflow more efficient.

Professional-Grade PU

Material — Flexible, durable, and color-stable over time.

Tangle-free recoil — Instantly recoils and

keeps your area neat.

Lightweight & Easy to

Handle — Reduces fatigue and improves productivity.

Stable Pressure

Performance — Working pressure up to 12 bar, safe and dependable.

Custom Color Option — Pink is an OEM / ODM

exclusive color, available upon request.

Applications

Automotive Repair: Ideal for ratchet wrenches,

grinders, and other air tools — safe, visible, and easy to manage.

Tire & Assembly Work: Strong coil memory provides

fast recoil and smoother workflow.

Industrial Air Supply: Connects compressors and

machine tools with stable airflow and quick identification.

Light-Duty Use: Perfect for exhibitions, demo

stations, or compact workshops that value cleanliness.

Add a pop of color to your

workspace — the SHPI Pink Coil Hose isn't just about looks, it's built to

perform.

Specifications

Material

O.D. × I.D.

(mm)

Working

Pressure

Burst

Pressure

Total Length

(M)

Color

PU

8×5

12 bar

36 bar

6 / 8 / 10 / 12 / 15

Pink

(custom color)

We also offer ready-to-use

packages!

This hose can be pre-fitted with various couplers and shipped as a complete set

— no waiting, just plug and use.

Have an idea for your own hose

color, hose size, hose pressure, or custom specifications?

Reach out to the SHPI team — we can help bring your unique pneumatic

design to life.

Contact Us

Want to make your workshop

stand out?

Contact SHPI – The Hose & Tubing Expert for pricing, OEM color

development, or distribution inquiries.

CONTACT SHPI NOW >

Read More

DOT Brake Tubing and PU Air Hose | Application Solutions for Commercial Trucks and Industrial Pneumatics

In the North American Automotive Aftermarket, we understand that you seek more than just parts — you need the components that keep commercial vehicle air brake systems and automotive pneumatic equipment running safely and reliably.

Founded in 1983, SHPI brings over 40 years of Taiwan-based manufacturing experience.

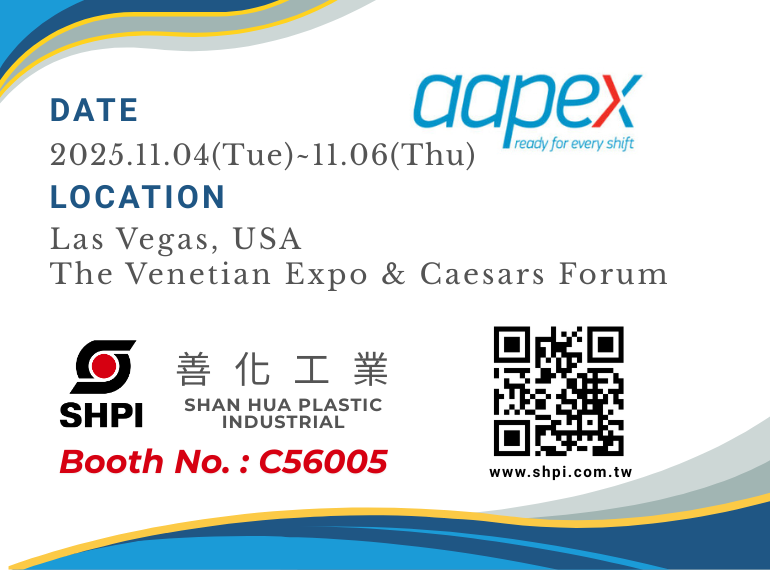

Our products comply with DOT FMVSS 106 (Federal Motor Vehicle Safety Standards), ISO 9001, and other international regulations, ensuring reliable, durable, and safe hose solutions for your operations.

At AAPEX 2025, we will present our theme "The Air Hose Expert", and we invite you to explore new possibilities in pneumatic technology with us.

Core

Product Lines : Hose

Solutions Designed for Your Real-World Applications

Every SHPI product is engineered based on actual usage environments, focusing on safety, durability, and long-term system stability — helping you meet the challenges of diverse working conditions.

DOT-Certified Air Brake Tubing

Brake systems allow no room for error.

SHPI Air brake tubing is certified to DOT FMVSS 106, ensuring zero-failure brake performance even under extreme climates and long-distance operations.

DOT-compliant fittings are available to support quick, safe, and reliable installation.

PU

Reinforced Air Hose

Constructed with a high-strength braided reinforcement layer, this hose withstands up to 300 PSI.

Ideal for automotive repair shops, factories, and heavy-duty pneumatic equipment, it effectively reduces burst risks and minimizes operational downtime.

Ether-Based

PU Hose

Formulated with an Ether-Based compound for excellent hydrolysis and moisture resistance.

It remains stable in humid and highly variable temperature environments and delivers over 50% longer service life, reducing maintenance and replacement costs.

PVC Hybrid

Air Hose

Designed for harsh and outdoor environments.

This specialized formulation remains flexible and crack-free in low temperatures.

Its low-memory behavior helps the hose lie flat, improving worksite safety.

Custom

Solutions for Precision Coating Systems (AAPEX Exclusive)

For automotive coating, spray booths, and high-cleanliness fluid systems, SHPI offers material and process-level customization.

These solutions are tailored based on actual application requirements and represent our premium technical service showcased at AAPEX.

Meet the SHPI Technical Team

If you require a more precise hose configuration tailored to your application, visit us at AAPEX 2025, Booth C56005, and book a one-on-one technical consultation.

We are ready to help enhance your system efficiency and long-term reliability.

SHPI Core Values: Your Long-Term, Trusted

Partner

We view international compliance, customization capability, and stable supply as long-term commitments to our customers.

✅ Zero-Risk Supply Chain

Complete batch traceability + stable supply agreements ensure uninterrupted production planning.

✅ OEM/ODM Customization

Dedicated colors and performance tuning to strengthen your product identity and competitiveness.

✅ Sustainability & Compliance

Formulations compliant with RoHS and REACH, supporting your entry into global green supply chains.

Secure Your AAPEX In-Person Consultation

We

look forward to meeting you in Las Vegas!

Curious how SHPI can improve your product

durability and competitiveness?

Reserve

your AAPEX 2025 consultation now and receive a complimentary OEM/ODM

feasibility assessment report.

Exhibition Information

Venue: Caesars Forum, Las Vegas

Booth: C56005

Date: November 4–6, 2025

Contact: info@shanhua.com.tw

SHPI – The Air Hose Expert

We

look forward to exploring the future of pneumatic hose technology with you.

CONTACT SHPI NOW >

Read More

【AAPEX 2025】Las Vegas | Automotive Aftermarket & Air Hose Sourcing Guide for Purchasing Managers

Why Start at Caesars Forum?

For professional B2B purchasing managers, time is not just about efficiency— it is the most valuable cost. With thousands of suppliers, you don't have extra time to shift through unnecessary information. Every step of your trade show journey must be precise and effective to connect with ideal supplier.

Don't worry —we prepared everything for you. This guide eliminates the hassle of planning, so you can stay focused on your core mission: finding valuable partners.

Caesars Forum is designated as the international sourcing area at AAPEX 2025. Here, leading manufacturers from Asia, Europe, and especially Taiwan automotive parts suppliers, gather in one location. This setup allows purchasing managers to save valuable time by screening and comparing suppliers more efficiently.

SHPI – The Air Hose Expert

At booth C56005, meet SHPI—Taiwan's largest pneumatic tubing manufacturer, specializing in solutions for automotive aftermarket repairs and commercial vehicle brake systems.

Automotive Aftermarket Repair:

SHPI provides PU Braided Hoses and PVC Hybrid Air Hoses that ensure pneumatic tools operate reliably under high pressure. Coiled hoses save workspace and improve onsite safety, reducing hidden operational costs.

Commercial Air Brake Systems:

DOT-certified Air Brake Tubing provides high-pressure resistance and excellent abrasion durability. These products ensure reliable braking performance even in critical situations, protecting both drivers and vehicles.

Your Efficient Sourcing Route

Starting at C56005, you are already in the golden zone of Taiwanese automotive suppliers. Here are some must-visit exhibitors nearby:

Rich Parts (C56001):Truck Aftermarket Parts

Just Auto Lighting (C56000):Automotive Lightening and Electronics

Jeesoon Terminals (C56006) 、 Hsin Kuang Bulb Works (C56004):Terminals and automotive bulbs

Yi-Way Industry (C56008): Precision Gears

Shuo Hong (C55001): Metal Forging and Machining

CTG Tools (C57002):Hand & pneumatic tools

With SHPI as your starting point, you can quickly navigate and connect with reliable Taiwan suppliers across multiple product categories.

Book in advance, Skip the wait

Save the time and avoid delays— book your appointment in advance via info@shanhua.com.tw.

Our team will be waiting for you at C56005.

Show Information

Show Dates: November 4 – 6, 2025

Venue: Caesars Forum, Las Vegas, Booth C56005

Book Appointment: info@shanhua.com.tw

AAPEX Floor Plan: Click Here

➡️ Discover PU Braided Hoses

➡️ Discover PVC Hybrid Air Hoses

➡️ Discover Coiled Hoses

➡️ Discover DOT-certified Air Brake Tubing

CONTACT SHPI NOW >

Read More

【SHPI Guide】How to Prevent Production Line Downtime | SHPI Pneumatic Tubing & Fittings Guide

Introduction: Why 24/7 Non-Stop Production Matters

In factory, the last thing you want to hear is: “Hey, the line just stopped!”

Whether fully automated or semi-automated, once the production line stops, output drops, cost increase, and all pressure falls on both engineering team and downstream customer.

Some people might ask:"Does a production line really need to run24/7? Can't it take a break like humans do?”

Unfortunately, the reality doesn't work like that.

Take the central air compressor as an example.

It must maintain stable pressure to supply the entire factory's pneumatic equipments. If it stops, every machine and tool that relies on compressed air goes down instantly. The same applies to injection molding machines, CNC machines, electroplating cells, and chemical tanks — all require continuous pneumatic air or fluid circulation. Even a short interruption can ruin production quality and lead to massive losses.

Instead of asking "Why must we run non-stop?”, the real question is "How can we make it non-stop?”

That's why SHPI prepared this quick Q&A guide – to help you diagnose the issue and find the solutions.

Q1: Why Is 24/7 Production Line Maintenance So Challenging?

There are countless reasons why a production line may stop. The trickiest one often the small thing that brings whole system shuts down. It happens normally like without routine machine maintenance, a part stuck in supply or even one air tubing/ pneumatic tube and makes it fail. For engineers, nothing is worse than“One tiny part caused the entire system shutdown.”

Q2: The Most Overlooked Pneumatic Parts: Tubes & Fittings

Tubes and fittings are often underestimated.

People tend to think,“It's just a tube, just a fitting.”

But in reality:

✅ Imprecise tubing tolerance leads to unstable air pressure and immediate yield loss.

✅ Poor-quality fittings waste hours in leak troubleshooting or get stuck during maintenance, increasing downtime risks.

Q3: How Do I Choose The Right Pneumatic Tubing?

The first step is always choosing the right tubing.

SHPI has prepared a detail comparison table of common pneumatic tubing characteristics and applications, ensuring you find the best match for your environment.

Tubing

Features

Applications

Polyurethane Tubing - ESTER

Light,

flexible, abrasion resistance

Dry

and general industrial environments

Polyurethane Tubing -ETHER

Hydrolysis,

anti-microbial, FDA compliant

High

humidity, outdoor, food processing

Nylon

Tubing-PA6

High rigidity, high pressure resistance

CNC

machines, industrial environment

Nylon

Tubing-PA12

Low

moisture absorption, UV resistance, abrasion, chemical resistance, FDA

compliant

Semiconductor, automotive,

outdoor

LDPE

Tubing

Chemical

stability, FDA compliant

Drinking

water, food processing, chemical, cooing water

Anti-Spark Tubing

PU inner layer(lightweight& flexible) + UL94

V-0 flame-retardant jacket

Welding,

cutting, high spark zone

Q4: How Else Can I Reduce Downtime Risks?

✔ Use SHPI One Touch Fittings

High precision, leak-free, and tool-free. Operators can replace a tube with just one hand, instantly boosting maintenance efficiency.

✔ Adopt Spare Parts Management

Treat tubing and fittings as consumables. Build a modular spare parts inventory, and let SHPI supply them on schedule. Maintenance becomes as simple and quick as swapping consumables— no more waiting for missing parts.

Q5: What Difference Will It Actually Make?

By addressing tubing and fittings at the root, you will:

✔ Dramatically reduce downtime risks— stable pressure, stable yield.

✔ Increase maintenance efficiency— quick replacements, like consumables.

✔ Simple operation— one-hand, intuitive fitting replacement.

In short: less downtime, fewer repairs, and stable productivity.

Q6: How Often Should Pneumatic Tubing Be Replaced?

This is the most common on-site questions.

The answer depends on the "working environment".

The key point is not about how long it lasts, but about replacing it at the first sign of problems.

The tubing cost is small, but a burst tube causes massive downtime cost.

Tubing

Type

Recommend

Check Cycle

Notes

PU

Tubing (General Factory Environment)

Every

1-2 years

Replace

when hardened, cracked

or discolored

PU Tubing / Nylon Tubing

(High Humidity or Food Processing)

About

1 year

Moisture,

cleaning agents speed up aging

Nylon Tubing

(High Pressure or High Frequency Use, e.g. CNC, Automotive)

Every

6~12 months

keep

spare tubes ready on site

Special

Environment

(Welding, Outdoor, Chemical Exposure)

Quarterly

Replace

earlier if sign of wear appear

Conclusion: Build A Stable 24/7 Production Line With SHPI

Achieving non-stop production is not about pushing equipment to the limit – it's about choosing the right tube and fittings, combined with smart maintenance planning.

Contact SHPI today for high-quality pneumatic tubing and one-touch fittings.

Together, we'll help you build a stable, reliable, and truly continuous 24/7 production line.

CONTACT SHPI NOW >

Read More

2025 AAPEX

AAPEX is the leading and the most representative exhibition in North America, focusing on automotive repair tools. As Taiwan's leading manufacturer in the pneumatic tubing and hose industry, SHPI will participate in the 2025 AAPEX to showcase our advanced technology and application capabilities across hardware, automotive and industrial sectors, while engaging directly with global buyer and partner.

With years of dedicating to the B2B market, SHPI provides OEM/ODM service. We look forward to collaborating with partners worldwide to create mutually beneficial opportunities.

Trade Information

Exhibition Name: 2025 AAPEX

Date: 2025/11/4-11/6

Location: Las Vegas

Booth No.: C56005

Products

Products

Application

Reinforced

Polyurethane Air Hose

Hardware、Automotive

Repair Tools、Pneumatic Tools

Coiled

Reinforced Polyurethane Air Hose

Machine

Tools、Assembly

Plants、Auto Repair Shops

Coiled

Polyurethane Air Hose

Machine

Tools、Industrial

Manufacturing

Hybrid

Air Hose

Hardware、Automotive

Repair Tools、Pneumatic Tools

Coiled

Air Brake Hose - SAE J844

Braking

System

✅Applicable Industries:

Hardware、Automotive Repair Tools、Pneumatic Tool Industry、Vehicle Braking System

Contact Us

Email: info@shanhua.com.tw

Tel: 06-2304567

www.shpi.com.tw

CONTACT SHPI NOW >

Read More

News

TRIED. TESTED. AND WANTED.